Tyre control effectiveness lessons learned

Tyre related accidents and incidents - A study with recommendations to improve tyre and rim maintenance and operational safety of rubber earthmover equpment

Tyre, rims and wheel assemblies are safety critical items which must be maintained and operated correctly to provide a safe working environment.

Unfortunately less than adequate (LTA) awareness of ‘off the road’ (OTR) tyre and rim related hazards, and lack of application of correct and proven approaches to deal with these hazards, in both the maintenance and operations areas continue to cause tyre and rim related accidents and incidents across the industry, some of them fatal.

This review has shown that OTR tyre maintenance and service work in particular is a high risk activity as it involves working with a number of high potential energy and hazard sources. At the immediate work interface, tyre maintenance by its nature requires the tyre serviceman to use compressed air to inflate tyre assemblies, use heavy manual and hydraulic tooling such as very large vehicle jacks and various other equipment, often air over hydraulic to break apart wheel assemblies and utilise bulky tyre handlers to manipulate the very large and heavy earthmover tyres and rims, to mention a few hazards that have played part in the causation of many incidents and accidents. Inflated tyre assemblies both off and on vehicles pose another important set of hazards.

Fit for purpose, tyre maintenance equipment and management practises for non-earthmover mining vehicles

Tyres, rims and wheel assemblies are safety critical items which must be maintained and used correctly to achieve levels of acceptable risk. Inadequate tyre and rim maintenance carries considerable inherent risks of personal injury and death, as tragically confirmed through several tyre and rim related fatalities in the Australasian region over the last few years, including some involving non-earthmoving equipment.

As such this project report aims to identify tyre maintenance safety issues around non-earthmoving vehicles and mobile equipment, and demonstrate effective solutions such as better tooling, improved maintenance equipment, improved safe work practises, and other recommendations for safer work.

Split rim wheel and tyre assembly

A Coronial Inquest into the death of a maintenance fitter was recently held following a fatal accident on a minesite. The fitter received multiple injuries when a split rim wheel and tyre assembly failed catastrophically whilst being fitted to a mobile crane.

The outer section of the cast iron split rim failed allowing a sudden release of energy. The wheel components along with the fitter were projected some 13 metres in the blast.

The jury found that the death arose by way of accident and the Coroner, on the recommendation of the jury, issued two riders as part of his findings:

Use of tyre inflation cages

Some mining operators rely on tyre inflation cages to control the risk of a tyre burst when inflating (and testing) newly assembled light vehicle tyres and on-highway type truck tyres (up to 24 inch rim diameter). Many of these cages are of unproven or uncertified design, and lack comprehensive instructions.

There is no Australian or international standard for the design, manufacture or testing of tyre inflation cages for any size of tyre. However, tyre inflation cages are commercially available in Australia, for tyres with rim diameters less than 24 inches, that are engineer-designed, third-party tested and certified to manufacturer’s standards.

Handling earthmoving equpment tyres

The Western Australian Department of Mines and Petroleum (DMP) released Safety Bulletin No. 89 on 13 November 2009 about a series of incidents involving earthmoving equipment tyres and the operation of tyre-handling machinery. There have been seven fatalities involving the handling of tyres at various Australasian mines in the past few years. Many in the mining industry are not sufficiently aware of the hazards involved in working with earthmoving equipment tyres and safety procedures are not always followed. Earthmoving equipment tyres, rims and wheel assemblies must be regarded as safety critical items that need to be maintained by competent people in accordance with documented systems of work addressing all of the risks involved.

Informative incident investigations

New South Wales Resources Regulator. Learning from investigations: Tyre handler fatality, Bengalla Coal Mine

On 3 November 2018 a Marathon Tyres worker at Bengalla Mine was replacing a tyre from a water cart. Operating an Omega tyre handler, the worker took the damaged tyre and rim to the mine’s heavy vehicle wash bay. While maintained in the grabs of the tyre handler, the worker positioned the tyre, suspending it off the ground. Using a high-pressure water cannon the worker cleaned the rim. The worker then entered a restricted work zone to obtain a hand-held hose. At this time the tyre unintentionally dislodged from the grabs and fell on the worker, causing fatal injuries.

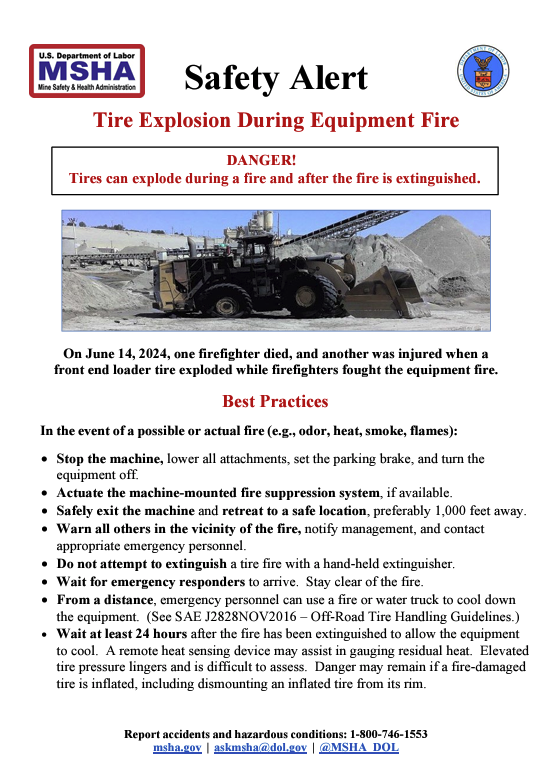

Tire explosion during equipment fire

A firefighter died while fighting a fire on a front-end loader. The victim was approximately four feet away from the tire when it ruptured, throwing him a significant distance away from the front-end loader.

Investigation report: Fatal machinery accident

On April 9, 2023, a miner died while mounting off road truck tires on rims. The miner was in the process of mounting a tire on its rim when another tire’s outer lock ring dislodged, became airborne and struck the victim in the head.

Investigation report: Fatal machinery accident

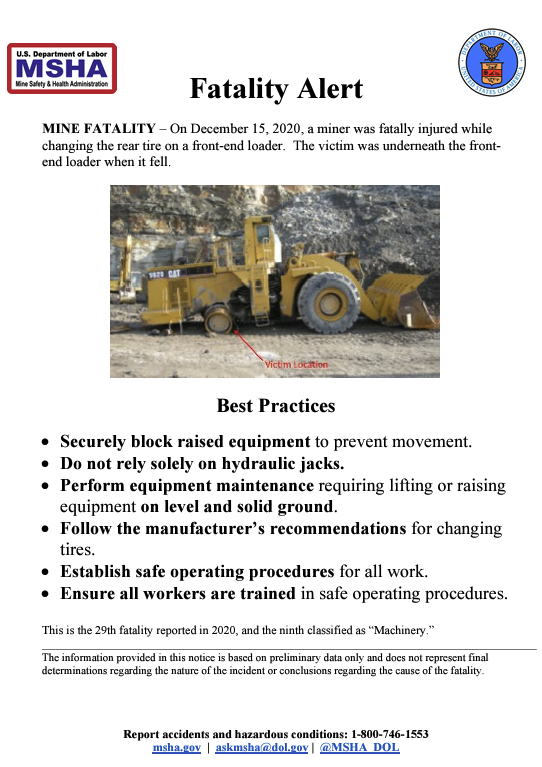

On December 15, 2020, a miner was fatally injured while changing the rear tire on a front-end loader. The victim was underneath the front-end loader when it fell.

The accident occurred because: 1) the contractor did not block the machine to prevent it from rolling or falling, and 2) a miner parked the machine at a site prepared by a member of mine management. The site was on unconsolidated fill material that was not level and stable for the tire change.

Investigation report: Fatal machinery accident

Santiago Cortez, tire company serviceman, age 49, was fatally injured about 3:30 p.m., March 15, 1997, when he was struck by a tire he was mounting on a front-end loader. Cortez had worked in the tire service business as an employee for 17 years, and had 11 months mine related experience. He had not received training in accordance with Part 48, but was task trained in April of 1996.